Software Precision for Rubber Production

RubberIQ is a dedicated solution for rubber factories, turning manual checks into real-time, data-driven quality control.

Follow each lot from natural rubber to processed product with full traceability. Ready for seamless integration into tire manufacturers’ supply chains.

Quality Control

Maintain rigorous standards with digital linking of lab quality data to every pallet produced.

Profitability

Improve profitability by delivering client-specific quality.

Traceability

Full traceability from natural product to processed goods, ensuring EUDR compliance and confidence.

Integration

Seamless integration with existing systems and processes, ensuring a smooth transition.

Offline Capability

Work offline, ensuring uninterrupted production even in remote rural locations. Install locally and sync with the SaaS in the cloud when internet is back up.

Cost Saving

Save costs by monitoring production parameters and optimizing acid consumption.

Ease of Use

User-friendly and easy to navigate, taking into account the needs of production personnel.

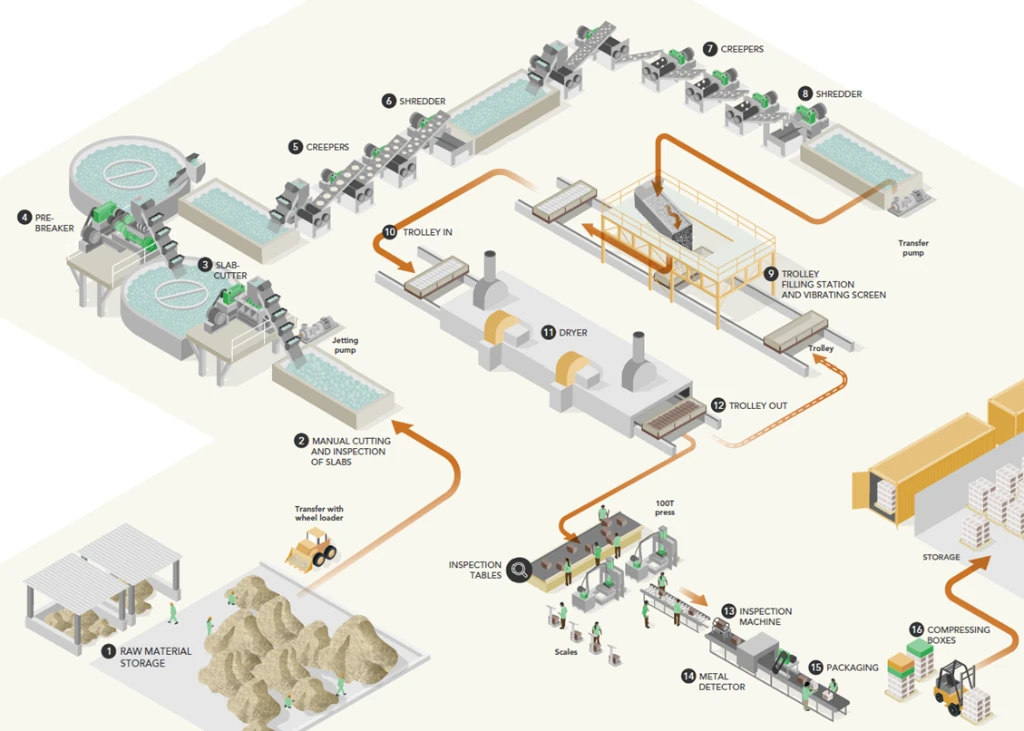

See RubberIQ in Action

Discover how our platform can transform your rubber production process with digital precision and complete traceability.

Request a DemoPowerful Modules for Rubber Production

RubberIQ offers specialized modules designed to streamline every stage of your production process.

Improve quality, costs and traceability in the whole zone between the bunkers and the shipping containers, including the dryer exit & the lab.

Label-IQ

Streamlined generation of QR codes for shipment towards factories of Michelin and other tire manufacturers. Ensure seamless traceability and compliance with industry standards.

- Automated QR Generation

- Michelin Compliance

Sample-IQ

Linking rubber pallets digitally to lab quality data and production parameters immediately after drying.

- Inventory Tracking Integration

- EUDR Compliance Data

- Lab Quality Linkage

Client-IQ

Optimize assigning pallets to a certain client and their Cp and Cpk specifications. Fill containers with minimal standard deviation of the client's specifications.

- Pallet-to-Client Assignment Optimization

- Cp and Cpk Calculation

- Minimal Standard Deviation Container Filling

Production-IQ

Improve statistical process control (SPC), Made-to-Order percentage and acid consumption optimization.

- Statistical Process Control (SPC)

- Made-to-Order Percentage Tracking

- Acid Consumption Optimization

Lab-IQ

Replace manual notes in the lab. Improve accuracy through electronic data read-out of lab equipment.

- Digital Lab Notes

- Electronic Equipment Data Read-out

- Automated Data Collection

Claim-IQ

Online information sharing on non-conformity with end-client. Store and share information such as container photos, production data and corrective action measures.

- Non-Conformity Information Sharing

- Container Photo Storage

- Corrective Action Tracking

Contact Us

Get in touch with us to see how RubberIQ can transform your production process.